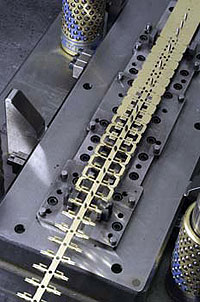

Progressive Die Tooling

We offer expert die tooling crafted on state-of-the-art equipment. All die sets have ball bearing pins and posts, and dies are made with guided stripper plates to provide for small sections. To ensure high speed production, lifters are incorporated into the die, while flatness correctors have been added to accommodate straight parts.

All stations are made with replaceable sections or inserts for infinite die life. In addition,

- Idle stations are incorporated into the design for possible future modifications.

- Trimming/blanking stations are made with carbide punches and bushings for low die maintenance and long life.

- Bend stations are multiple qualified to hold angle tolerances.

- Forming stations are made with sintered carbide tool steel for long life and low maintenance.

- Electronic Discharge Machining (EDM) is used for punches and inserts for precision accuracy and reproducibility.

Request a quote.

|

|

Custom Solutions

Custom Solutions