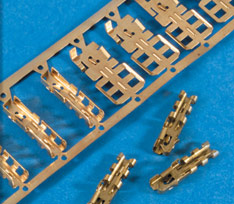

Maximizing Your Efficiencies

Our metal stamping process ensures fast turnaround and provides built-in cost saving features. For less complex components, we offer an accelerated turnkey process that lets us help you quickly and economically meet your production demands. Ask us to quote your next project! Our metal stamping process ensures fast turnaround and provides built-in cost saving features. For less complex components, we offer an accelerated turnkey process that lets us help you quickly and economically meet your production demands. Ask us to quote your next project!

Equipment

Zierick uses best-in-class metal stamping equipment, consisting of the following high speed presses:

- Bruderer 30-ton

- Minster 32-ton

- Minster 60-ton

Capabilities

| RoHS Compliant |

|

| Material Thickness: |

0.001" to 0.064" |

| Size: |

< 2-1/2" |

| Square Formed Angular Tolerances: |

+/- 2 degrees typical |

| Cut Angular Tolerances: |

+/- 0.5 degrees |

| Manufacturing Tolerances: |

+/- 0.005" |

| Typical Materials: |

C17200 Beryllium Copper |

| |

C26000 Brass |

| |

C11000 Copper |

| |

C51000 Phosphor Bronze |

| |

Bronze (CDA 425000) |

| |

Steel (low/high carbon and stainless) |

| |

Other specialty Alloys |

| *Slot Size less than 3 times the material thickness can add considerably to die costs. |

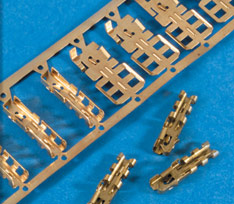

In-House Plating

Our In-House barrel and strip plating lines guarantee quality and improve turn-around time.

Request a quote.

|

|

Custom Solutions

Custom Solutions

Our metal stamping process ensures fast turnaround and provides built-in cost saving features. For less complex components, we offer an accelerated turnkey process that lets us help you quickly and economically meet your production demands. Ask us to quote your next project!

Our metal stamping process ensures fast turnaround and provides built-in cost saving features. For less complex components, we offer an accelerated turnkey process that lets us help you quickly and economically meet your production demands. Ask us to quote your next project!